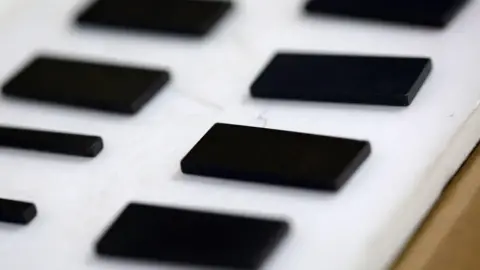

In November 2025, India approved a 73bn-rupee ($800m; £600m) plan that could help it to cut its dependence on China in one of the most strategic corners of the global supply chain: rare earth magnets. These small but powerful components sit at the heart of modern life – used in everything from electric vehicles and wind turbines to smartphones, medical scanners, and defense equipment. Developing a full rare earths ecosystem is expensive, complex, and time-consuming. By focusing on magnets instead, one of the most widely used rare-earth products, India aims to achieve self-reliance more quickly. But its success will depend on how fast the country can master technology, secure materials, and scale up, experts say. Under the scheme, selected manufacturers will receive capital and sales-linked incentives to produce 6,000 tonnes of permanent magnets a year within seven years, aiming to meet rising domestic demand, which is expected to double in five years. Industry experts warn that money alone will not be enough, as India today imports 80-90% of its magnets and related materials from China. That dependence was exposed last year when China tightened exports during a trade dispute, impacting Indian carmakers and electronics firms, and forcing the electric vehicle industry to explore alternatives to rare earth magnets. India's challenge is compounded by a lack of industrial expertise; countries like Japan and South Korea have refined magnet-making technology over years, while India has virtually no commercial-scale experience. Although the introduction of the scheme acknowledges India's ambition to strengthen its rare earth ecosystem, experts highlight the need for strategic partnerships, investment in workforce skill development, and addressing the complexities of raw material extraction and processing.

India's Move Toward Rare Earth Magnets: Hopes and Challenges

India's Move Toward Rare Earth Magnets: Hopes and Challenges

India is attempting to reduce its dependence on China for rare earth magnets, crucial for electric vehicles, electronics, and defense. With a new $800 million initiative, can India build its own magnet manufacturing capacity?

India has initiated a $800 million plan to develop its own rare earth magnet manufacturing, aiming to decrease reliance on Chinese imports. However, challenges remain, including technological expertise, raw material availability, and competitive pricing. Industry experts emphasize the importance of strategic partnerships and scaling production quickly to meet rising domestic demand.